Captivating Moments

Get captivated by a stunning collection of images showcasing various subjects in our meticulously curated gallery.

Product Information

Industrial automation is the backbone of modern manufacturing, simplify processes to deliver precision, reliability, and efficiency.

These systems have two main parts: PLCs (Programmable Logic Controllers), and Drive Control Panels.

Together, they create a connected system. This allows for easy control and automation. It works for motor systems and large production lines.

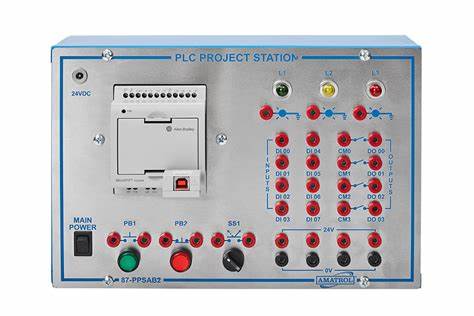

The PLC Control Panel is important for managing and housing the PLCs. It helps ensure smooth operation and integration in complex industrial automation.

What is a PLC (Programmable Logic Controller)?

A Programmable Logic Controller (PLC) is essentially the “brain” of automation systems. PLCs are specialized, ruggedized computer designed for real-time control of industrial processes and machinery. Programmers create PLC Control Panel to monitor system inputs.

They make logical decisions and execute outputs accurately.

Core Functions of a PLC:

. Input Processing: PLCs receive signals from sensors, switches, and other input devices within a system.

These inputs provide real-time data about the state of the process or machinery.

. Decision-Making: Using pre-written programs, the PLC processes inputs and makes logical decisions to determine the required outputs.

. Output Control: Once decisions are made, the PLC controls actuators, motors, and other devices to manage machines and systems.